Fans and Blowers

<>Centrifugal fans

Axial fans

Ventilating fans

Roof exhausters

Panel fans

Fume exhaust fans

Fiberglass fans

Industrial exhausters

Heavy duty fans

Pressure blowers

Custom engineered fans

Heating and cooling coils

Air preheater coils

Custom air handling units

Make-up air units

Industrial sound attenuators

Replacement fan parts

|

|

| Heat Exchangers

- Heating and Cooling Finned

Coils

- Liquid-to-Air and Air-to-Air

Heat Exchangers

- Industrial process heat exchange

coils

|

|

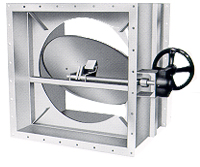

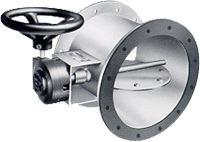

| Dampers and

Actuators

- Fan and blower dampers

- Isolation / flow diverter

industrial process blower dampers

- Fan louvers and shutters

|

|

| Air Systems

- High penetration air knives

and air cannons

- Air curtains / gas gates / air

screens

- Material handling & pnematic

conveying blower systems

- Dust collecting systems and air scrubber blowers

|

|

| Silencers and

Enclosures

- Blower and fan silencers

- Sound enclosures

- Vibration eliminators

|

|